Heating furnace for parabolic rolling machine with automatic output roller convey

1) Contour sizes (mm): 5800 ×2300 ×1640mm (L×W×H)

2) Max. Capacity of furnace: 3 pcs/min (standard leaf16*90*500mm)

3) Effective heating length 200~900mm

4) Heating temperature 900~1000°C

5) Accuracy of temperature control: ±10°C (controlled automatically)

6) Fuel: LPG

7) Way of loading: Walking beam step loading

8) Burners: KromSchroder

9) The temperature control is done via two ways

A. Thermocouple (the main measuring device)

B. Infrared Pyrometer (the secondary measuring device).

10) Temperature controller: brand SHIMADEN, serial SR93. with highest temperature setting.

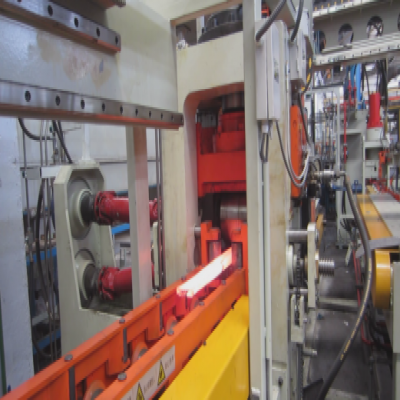

Mechanical driven parabolic rolling machine

1)Max. Capacity of horizontal roller: 100 Ton

Max. Capacity of vertical roller: 10 Ton

2)Working Diameter of horizontal roller: 220~200mm

3)Working Diameter of vertical roller : 120~100mm

4)Rolling speed: >400mm/second

5)Thickness before rolling: 10~60mm

Min. thickness after rolled: 5mm

Leaf width: 50~120mm

6)Length of leaf before rolling : 800~2000mm

Length of leaf after rolling 1200~2500mm

Max. rolled length of each rolling end 1300mm

Min. rolled length of each rolling end 1000mm

7)Tolerance of rolling : (±0.15mm Thickness)

(±0.50mm Width)

8)Efficiency for rolling length around 1000mm, 4 passes ≤55sec

9)Max. carriage Cylinder stroke 1700mm

10) Max. Ration (rolling thickness vs length) 1: 8

11) Proportion Servo valve: BOSCH

12) Control monitor - reputable China brand is acceptable

13) Hydraulic Coupling & Joints - Taper seal type

14) MAIN MOTOR - SIEMENS brand (Made in China),

15) Hydraulic component: Rexroth Series, made in China

16) Main electric component: Schneider

17) PLC : Mitsubish

.jpg)

.jpg)

.jpg)

.jpg)