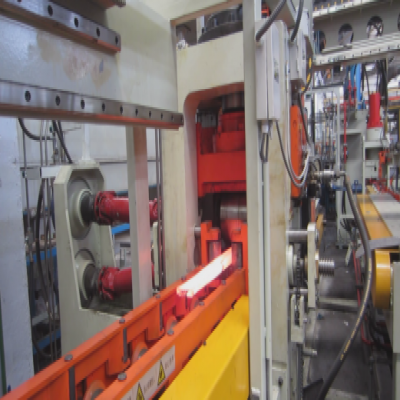

DZN Parabolic Rolling Machine(roller driven by hydraulic units)

DZN parabolic rolling line, the roller driven by the hydraulic device,is designed with higher configuration and higher rolling efficiency, with the rolling ratio 1:4.

Main technical parameter for Parabolic Rolling Machine

1.Max. Capacity of horizontal roller 76TON

2.Working Diameter of horizontal roller 200~180mm

3.Working Diameter of vertical roller 120~100mm

4.Rolling speed 500mm/second

5.Idle speed 1000mm/second

6.Thickness before rolling 5mm

Min. thickness after rolled 10~60mm

Leaf width 45~120mm

7.Length of leaf before rolling 780~2200mm

Length of leaf after rolling 800~2500mm

Max. rolled length of each rolling end 1300mm

8.Tolerance of rolling (±0.15mm Thickness) (±0.5mm Width )

9.Efficiency for rolling length around 1000mm 4 passes ≤25sec

10.Power of the motors 4*37Kw

11. Max. carriage Cylinder stroke 1700mm

12.Max. Ration (rolling thickness vs length) 1:4

13.Proportion Servo valve BOSCH

14.Hydraulic component Rexroth Series, made in China

15.Main electric component Schneider

16.PLC Siemens S7300

Main technical paraeter for heating Furnace

1.Contour sizes (mm)5800 ×2300 ×1640mm (L×W×H)

2.Max. Capacity of furnace 3 pcs/min (standard leaf 16*90*500mm)

3.Effective heating length 200~900mm

4.Heating temperature 900~1000°C

5.Accuracy of temperature control±10°C (controlled automatically)

6.Fuel LPG or natual gas

7.Way of loading Walking beam step loading

8.BurnersKromSchroder

9. The temperature control is done via two ways

A.Thermocouple (the main measuring device)

B.Infrared Pyrometer (TXCHTSF) (the secondary measuring device)

10.Temperature controller SHIMADEN, serial SR93. with highest temperature setting.